It is not authoritative and not necessarily the correct way. Being the first there is no precedence.

Yvonne’s shoulder has been loose for many months. First officially reported in May. With a very loose rotation along the axis it was difficult to keep her arm from flopping around during ‘play‘ and posing.

As has been said in the ‘Joint Tightening’ thread, joints do loosen and are better left if it does not cause a problem. However, when it interferes with both play and posing and also locks or freezes because something is jamming - as with Nony - then a repair is necessary.

It must be said that Yvonne was the first production model and Knighthorse have probably learned as much from me as I from them. So this repair was a learning curve for both of us and future models hopefully will have improvements, better quality contol and refined production techniques from the lessons learned.

Well, first up we gotta open her up and have a look to see what is happening.

It can be very scary to cut open a doll. Some say “Oh! I cannot do that.” I did too in the beginning just over a year ago when I had to work on Natasha. Trust me, I am not a craftsman by any stretch of the imagination and cannot match the skills of Mechwizard, Incrediwagon, CJD, Litlluvr, Mahtek - to name just a few - but I am not unhappy with the results and if I can do it, anyone can do it. (That was written before I had to cut again at the second attempt, now I am not so Happy).

Tip: Practice first on samples and test your techniques and the materials you use.

OK, so when we open up we can see what happened.

A bolt unscrewed and jammed against a shaft. But why?

Well, as there is no clearance between the Bolt head and Shaft when the arm is adducted/abducted around 45 degrees plus or minus say 10 degrees, every time Nony’s arm was flexed and extended (forward/back) in that position the rim of the shaft rubbed on the bolt head and unscrewed it. As can be seen here.

The hex head set screw specifically there to stop it unscrewing failed to do so.

You can see the set head screw hole in the photo. Totally inaccessible so unable to use.

Both the clearance and set screw issues have been addressed by KH I am advised.

(There is maybe another reason?, possibly the main reason, which is described later when I had to do the job again - see second attempt below). Anyway,

In order to tighten the bolt you have to remove the shaft bolt.

This is a bit awkward because it is a long bolt so the silicone skin has to be pulled right back and as it was a tight fit in the shaft it had to be unscrewed all the way instead of just pulling it out. You can see the threads in the shaft bolt hole. The sort of job where you wish you had four hands.

Once removed you just shift the shaft out the way and tighten the bolt.

As the set screw is not accessible I thought to drill a hole in the top and thread my own screw in to hold the bolt. However the thickness of the shaft and difficulty of doing this ‘at home’ on one’s own made me decide to forget that idea & loctite the bolt using their low strength threadlocker (Loctite 222). (This failed but I did not know at the time - see second attempt).

Before doing so however it is important to tighten the bolt and test the torque required for satisfactory tightness and movement of the joint. Because you cannot spend too much time to adjust it once the loctite is applied without destroying it’s threadlocking. Trust me, it needs to be tightened very, very hard indeed.

So, undo the bolt, apply the loctite (ensuring the washers, bolt & U housing are positioned and assembled correctly) and tighten it up. Partial cure in 20 minutes, full cure in 6 hours.

Now comes a messy bit.

In order to ensure there is no chance of the shaft interferring with the bolt again I decided to trim up the edge of the shaft. Probably not necessary as the rim was already worn flat, but just in case. One could use a file but that is a bit fiddly and as I have a dremel I used that.

I practised on a piece of aluminum flat plate first with many different attachments. The small thin disc worked best.

Specks of alumimum metal everywhere so a clean up was required.

Tip: Alcohol works fine but have plenty of cloth handy as you can only wipe once in one direction then you have to use a new bit of the cloth. If you don’t the specks you just picked up get re-deposited.

Put the shaft back in.

This is also an awkward job to get the shaft, washers and holes lined up at the same time as holding back the silicone and screwing in the bolt. I used a 90 degree screwdriver to keep one end positioned while screwing in the bolt from the other.

Tighten up the bolt and nut to your desired tightness.

Check to make sure everything is in place correctly and all tightened to your satisfaction.

Position your girl with pillows or whatever so the silicone closes pretty much naturally and is all lined up. (no longer possible with the distortion of the cut made for the second attempt).

In the photo I am actually holding her cut slightly open so you can see it, if I let go the cut would close completely. That way you do not have to strain to hold the join together when the adhesive is applied.

And you are now ready to close up.

However, before closing test rigorously. I tested, but not rigourously enough, and thus failed to notice the loctite was inadequate.

With such a thick cut one has to close in stages. Deepest first.

After she was back on her stand, and after a couple of movements all I ended up with was a limp appendage hanging from her shoulder. No flexion / extension holding force whatsoever.

Second Attempt.

It was clear the bolt had unscrewed and would continue to be a problem so a reluctant second attempt was necessary. Yes, necessary, not an option., there was a loose unscrewed bolt inside.

Cutting open over an already cut wound is ‘unfortunate’. As the silpoxy adhesive used to close the first time and the original silicone skin are dissimilar and as it is impossible to cut exactly down the same first cut the wound opens in a distorted way.

No nice clean matching closure line this time. There will be a significant scar. Perhaps a good place for a big tatoo?

Well if loctite is not enough to hold the bolt then, in the absense of any alternative advice, I decided to fit a screw.

Drill the hole. (3.5mm twist drill)

Remove the metal shavings. Piece by piece with tweezers.

Clean up as best as can with cloth and alcohol. (As described earlier).

Tap in a thread. (4mm bolt).

(Having tested the principle first on a practice piece).

I tried using a hex head set screw (grub screw) however this failed and led to near breakage of the allen key. So I decided to use a 4mm screw.

But first it had to be trimmed lengthways to fit and have the end tapered.

I used my test hole, a bolt to hold it steady and a dremel for this.

Then I screwed in the bolt, tightened up the fixing screw and rigourously tested.

The bolt unscrewed. Shit.

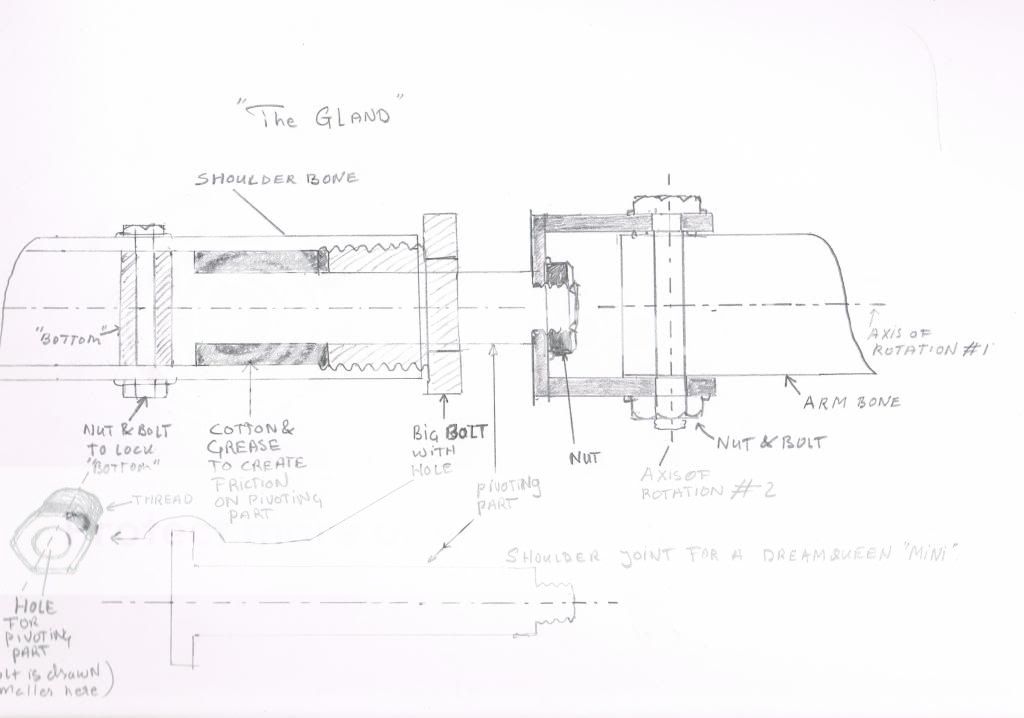

OK. What is happening is that the U housing swivels, the nylon washers are supposed to slip on it to provide the movement and then grip. The force required to tighten the bolt sufficiently for the ‘grip’ part of that to hold her arm up against gravity is so great (remember levers) that the pressure of the washers also act to undo the bolt head and the screw is not applying enough pressure on the bolts thread to hold & stop it.

What next? I took it all apart. Assembled the bolt, U housing and washers and tightened to where it holds (I hope). I then drilled down with a 3mm twist drill into the threads of the bolt.

I trimmed up the end of the screw and fitted it down as tight as I could without srripping the head.

And tested.

It held. Unfortunately one is doing this blind. You cannot unscrew the bolt after drilling because there is no way to line up the drilled indentation in the thread with the hole again if moved.

I loctited the screw as tight as I could and now hope it is all tight enough and I got it right.

We will see. Tomorrow when I refit the shoulder joint (adduction / abduction) and test.